– Everything Aspiring Soldering Professionals Need to Know

People who aspire to be soldering professionals will feel happy to know that soldering is a very simple science. There are no secrets. It’s merely a matter of repetitively practicing some pre-established set of rules. Who sets these rules? The IPC or the Association Connecting Electronics Industries. This US-based trade association has been standardizing manufacturing processes of electronic components across the globe for more than sixty years. These standards are accepted globally, so all soldering and electronics assembly professionals are required to receive IPC training and certification. Without these certifications, soldering and electronic assembly professionals will find it hard to establish their credibility in the electronics manufacturing industry.

Table of Contents

What is STI Training?

STI Electronics, Inc. (STI) is a world-renowned provider of IPC training courses. Their courses are open to all – be it an experienced electronics assembly professional looking for recertification or an amateur looking to enter the industry. Apart from training industry professionals, STI provides consultancy services to Original Equipment Manufacturers and also invests in scientific researches. In the market since 1982, STI training is the best tool for students who want to learn the nuances of soldering and creating PCB assemblies. The institute provides training courses for pretty much every IPC standard. They also offer customized courses.

What Solder Training Kits Will Students Require during their IPC training?

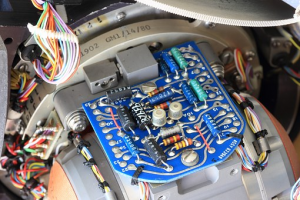

To partake in IPC Training courses on soldering, PCB Assembly, component inspection, and electronics manufacturing, students will require different types of materials and training kits. Each IPC standard is different, so the material requirements for each training course are different. For instance, let’s talk about the training kits, tools, and materials that students need in IPC J STD-001 training. Also known as ‘‘J Standard training,’’ this course is based on the IPC J-STD 001 document.

The certification program for ‘‘J Standard training’’ is multi-tiered, time-limited, and students have to pass tests to receive their certifications. Like most IPC training courses, there are different levels of certifications, with the highest level being the master instructor. These instructors are certified to provide training services to other professionals in credentialed training centers. These master instructors are officially known as certified instructors or CITs.

In IPC J-STD-001 training programs, students learn basic descriptions of the materials and techniques used to manufacture high-quality solder interconnections. Students also learn about important inspection criteria for confirming the quality of the components they manufacture. For instance, all solder interconnections need to be lead-free as per the latest IPC requirements.

For these training programs, students will require very basic solder training kits. Students applying for both Certified IPC Specialist (CIS) training and IPC Trainer (CIT) certification will require the same types of kits that contain materials like

- Lead Boards

- Watt Axial Resistors,

- T05 Transistors

- Transistor Standoffs

- Axial Diodes

- CKO6 Capacitors

- Capacitor Standoffs

OEMs who need highly trained workforces typically pay for their employees to receive IPC J-STD-001 training. Master trainers can visit company facilities and customize their classes based on the specific needs of the manufacturer.

How to Choose the Best IPC Training Center to Receive Certification?

Ideally, aspiring soldering and electronics assembly professionals should opt for IPC-certified training centers that have been in existence for over a decade. Experience in the IPC training industry is vital as it demonstrates the trainers’ abilities to motivate and inspire aspiring professionals consistently.

- Look for IPC-certified training centers that offer all types of IPC-based certifications.

- Check whether the training center offers online resources.

- Verify the experience of the instructors. How long have they been IPC-certified instructors?

- Make sure the training institute meets quality system requirements like ISO or AS9100.

Merely memorizing the IPC standards isn’t enough. Students must be able to explain the rationale behind the various guidelines in IPC standards after they complete their training.

What are the Costs of Training and Certification?

There’s no fixed STI Training Cost. Prices can range from $350-$2500 depending on factors like –

- The difficulty of the training course (how many training kits are required, the number of skills the students have to acquire, etc.)

- Length of the training courses. Some courses take three days; others take weeks.

- The number of instructors required to complete the class.

The type of certification the student is applying for also plays a part in training costs. For instance, IPC 7711 and IPC 7721 certification programs both cover similar topics. In IPC 7711 training, students learn how to rework PCB fixtures. In IPC 7721 training, students learn how to physically repair printed circuit boards using techniques like tracing, through-hole repairs, etc. Although both courses are similar, their costs are different, and the time required to complete these courses is also different.

What are the Career Opportunities for Professionals Who Receive this Training?

The global PCB market will be valued at over $89.7 billion by the end of 2024. So, there are plenty of career opportunities for aspiring soldering and electronics assembly professionals. Since IPC certifications are recognized globally, professionals who receive these certifications are valued immensely in the industry.